I had to cancel the print. There were a few flaws in the model that I couldn't ignore and that I wasn't able to see in the model itself. In particular the button mounting brackets were not attached to the sides of the case but just floating 1mm from the case. Rookie mistakes.

It's ok. This will allow me to make a few other refinements that I noticed when printing, but that weren't important enough by themselves to cancel it.

We are 40 hours in and the structure that holds the knitting machine itself is completed. All that is left are the walls which also have button and motor mounts in them.

After almost 16 hours, the case for my knitting clock is starting to take shape. You can now make out the central structure that will hold the knitting machine itself in place. While I tried to reduce overhangs, due to the nature of this model there still are quite a few so there will be a lot of internal support material to remove when this is done.

I've been quiet about my hackaday-inspired knitting clock project ever since I decided to replace the 48-hook machine with a 22-hook model, but that's because I've been busy learning 3D modeling!

I realized the new 22-hook knitting machine fits on my 3D printer bed, so instead of a wooden case, I designed a custom case for it using Tinkercad. I just started an epic 2 day, 8-hour print of the case that takes up my entire print bed!

In case anyone new to weaving is wondering how you recover from a mistake like this, measure out a new warp thread, thread it through the reed and heddle, and then hang it off of the back of the loom with a weight. I wrap the end of the warp around the weight until it hangs properly, and unwind it a bit every few times I advance the warp.

Then wrap the other end around a pin and pin it to the fabric. After enough rows eventually tension will keep it in place.

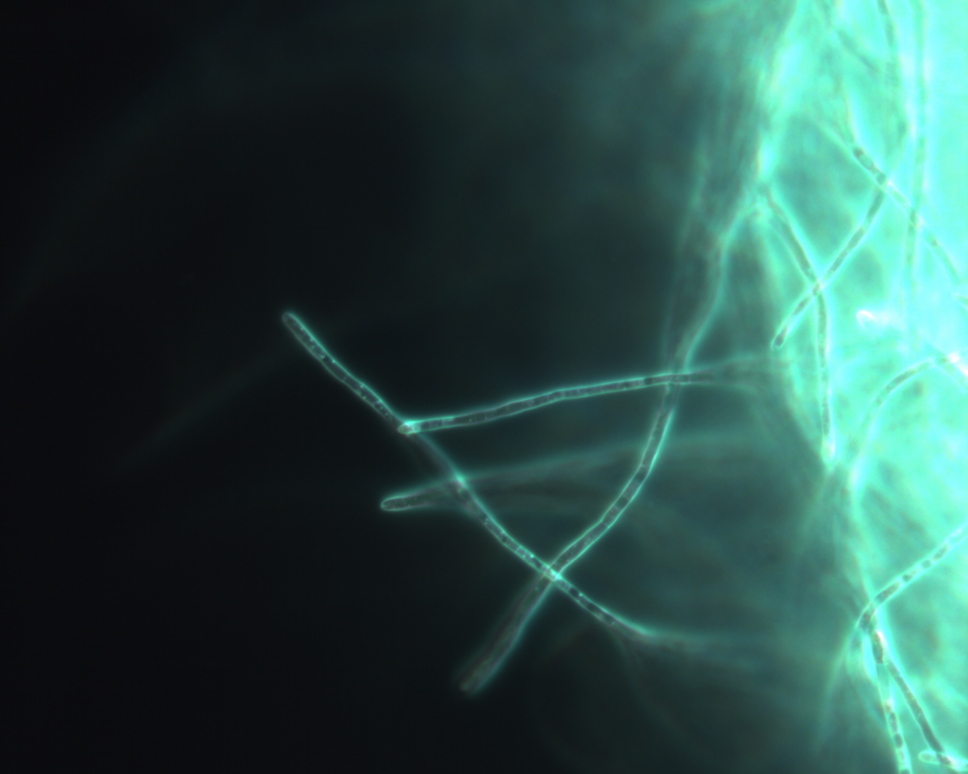

After weaving quite a few inches into the towel I thought something looked off and discovered I was missing a thread!

If you find the pin in the picture you can see that part of the pattern just looks a bit off. Follow that line up to where the thread finally is threaded and you can see where the pattern got corrected after I added a new warp thread.

I finished tying on the new warp to the old and have started weaving the first of three towels. Beyond the different colored yarn, I also modified this design in two ways, taking advantage of the reversible nature of this doubleweave overshot pattern:

1. Since there is no "right" side to this, I reversed the color for almost 2/3 of the hem at the bottom so when I fold it, it matches the color on its own side.

2. I extended the inverted color of the pattern stripe.

I'm very excited to announce a brand-new #podcast exploring the most intriguing conversations in #opensource brought to you by Intel’s Open Ecosystem group.

https://openatintel.podbean.com

The first season focuses on #security and features Christopher "CRob" Robinson, John Whiteman, and @pdxjohnny and is hosted by me, @katherined.

The first two episodes are out now, and there are more to come!

Halfway through tying a new warp onto the remnants of the old. Wow this is tedious work, and there is at least 3 more hours to go, but I still think it is faster and less error-prone than re-threading it.

If anyone can't smell, perhaps this is the mod for your Librem 5.

https://youtu.be/Xv0gXfxCKEA

#Librem5 #BreakoutBoard, #anosmia #hacker #hardware

I'm weaving a new set of towels using the same doubleweave overshot pattern as the last set, but this time using yellow and brown unmercerized cotton.

Because the pattern is the same, I can save time by tying my new warp onto the remnants of the old warp that are still threaded in the loom. You simply use a weaver's knot to tie each individual new warp thread to a corresponding old warp thread and then wind it back on. Only about 550 warp threads to go!

Now that the knitting machine is mounted on the board, you can really see how much space it would take up on the wall. We thought it over and decided to replace the large 48-hook version with the smaller 22-hook version.

Fortunately everything I did to the machine is reversible, and I still have the box and all the accessories. I know someone who I think will really like this one as a gift so it won't go to waste.

I’m sad to announce that I am leaving @themarkup to pursue other projects, which I will announce soon.

It was an honor and a privilege to found @themarkup five years ago to create an investigative newsroom that integrated engineers and journalists. We showed the world what journalism could be: math literate, computationally superpowered, and human-centered.

On my departure, I thought I would reflect on the ten lessons I learned leading these investigations. https://themarkup.org/hello-world/2023/02/04/journalistic-lessons-for-the-algorithmic-age

More progress on my knitting clock. I've mounted all of the main components to the backer board. I also wired two buttons to GPIO pins and wrote a simple script to advance the machine forward and backwards one stitch with the buttons. I'll likely use this when I'm casting on and casting off.

The top of the clock will be where the stepper motor is. Now that I know how the pieces fit, I will cut the top so it is house-shaped, and build the sides and front of the clock.

I wrote a blog post about the dangers of focusing too much on hardware specs to predict performance when choosing hardware. In my experience many other factors (such as the software the hardware will run) have much more of an impact. Focusing on specs alone incentivizes bad practices like planned obsolescence and disposable hardware.

U.S. border officials copy the contents of up to 10,000 phones and computers every year and save them to a big database for 15 years, as we first reported in September: https://www.washingtonpost.com/technology/2022/09/15/government-surveillance-database-dhs/

Following pressure from Sen. Wyden, the agency, CBP, now says it's considering shrinking that 15-year save time and plans to give people more details about what they're doing: https://www.washingtonpost.com/politics/2023/01/31/abraham-accords-expand-with-cybersecurity-collaboration/

I knitted a shawl! Well, the flatbed knitting machine did a lot of the work, but I helped. This was the second attempt as I ran out of yarn halfway through for the first attempt and the local yarn store only had the single skein. I ended up selecting a different yarn for this attempt.

All the functional pieces of my hackaday-inspired knitting clock are in place:

* Working circular knitting machine

* Spare Raspberry Pi I had lying around

* Adafruit motor control hat

* Spare stepper motor from a broken 3D printer

* Software to control the stepper motor

The next and more challenging step is to figure out the best way to attach the motor to the knitting machine and build an attractive case to mount everything.

- Personal Site

- https://kylerank.in

- Personal Bibliography

- https://kylerank.in/writing.html

Technical author, FOSS advocate, public speaker, Linux security & infrastructure geek, author of The Best of Hack and /: Linux Admin Crash Course, Linux Hardening in Hostile Networks and many other books, ex-Linux Journal columnist.