I was reading a book on the history of American coverlets and it referenced (and was clearly inspired by) this book, Keep Me Warm One Night, an exhaustive history of the Canadian coverlet weaving tradition. The book is out of print, and most of the used copies were rather expensive.

I found a copy for a more reasonable price so here it is, part of my weaving library! My mom has hinted she'd like a traditional coverlet, and it will likely be inspired by one from this book.

My towels are finished! I handstitched the hems with a felling stitch using matching thread so it would be invisible, and because this is a reversible pattern and has no "right" side, I put one hem on each side of the towel. In this picture you can see what each side looks like. The one on the left (with some treadling mistakes) I will keep and the one on the right will be submitted to a competition.

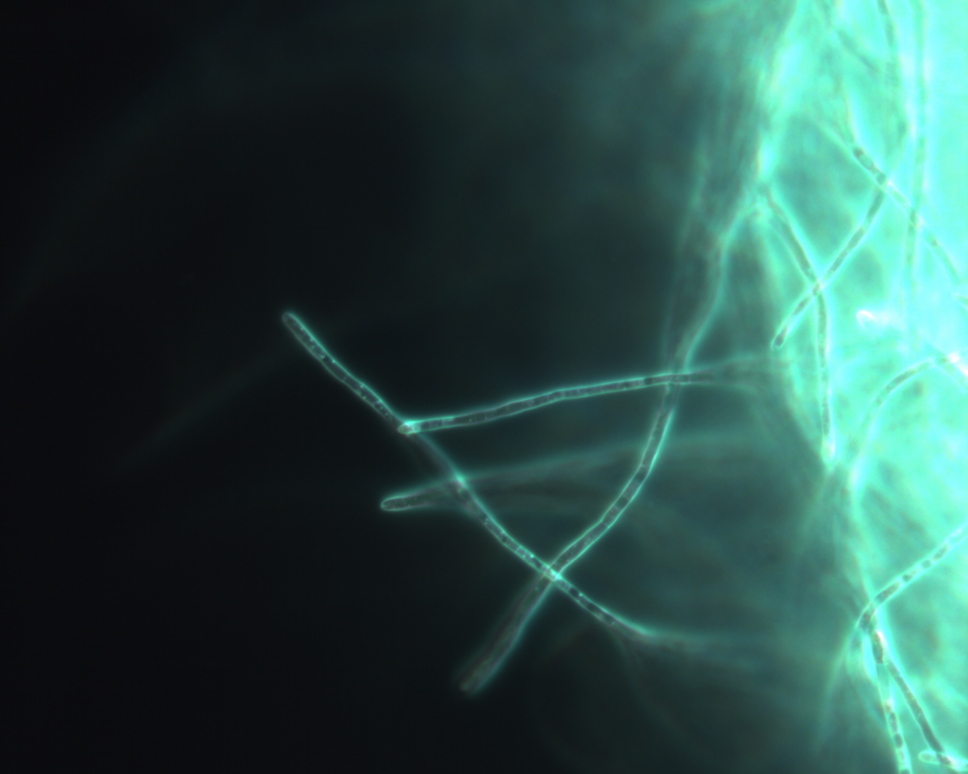

Well I think I'm calling it quits on this towel set early. This is the last in a long series of warp threads that came loose from the weaver's knot that attached it to the previous warp.

That by itself I could deal with, but what is worse is that all of the loose warp threads on either side of the weaver's knot are now tangling and making it almost impossible to get a shed without separating them each time the shed changes. I don't think I will tie onto an old warp in the future.

I *think* I have managed to talk myself out of getting a very affordable used 60" production mechanical dobby loom with all the automated attachments.

One against it is the fact that it would only fits in my garage, and by the time I could clear out the space it would likely be gone. Do I really want to do production weaving in my dusty garage?

Finally, I guess the biggest argument is that I can't justify actually doing mass production weaving since this is just a hobby.

I'm halfway through the second doubleweave overshot towel, and so far things are going smoothly and mistake-free! I probably won't do another update on this project until they are off the loom and hemmed, unless a fun disaster strikes.

My son completed his first weaving project (he's 10). This white and red striped wool scarf was woven on a rigid heddle loom.

One towel down, two to go! From this angle you can see both sides and the reversible nature of this doubleweave pattern.

See if you can spot the treadling errors! I managed to make the same mistake three different times in pattern repeats so far. Combined with the threading mitsake from earlier, this is rapidly becoming the "warm up" towel where I hopefully get all of the mistakes out of my system before the next two.

- Personal Site

- https://kylerank.in

- Personal Bibliography

- https://kylerank.in/writing.html

Technical author, FOSS advocate, public speaker, Linux security & infrastructure geek, author of The Best of Hack and /: Linux Admin Crash Course, Linux Hardening in Hostile Networks and many other books, ex-Linux Journal columnist.