@amanjeev @purism I apologize for the misunderstanding, I was not pinning anything on you, just making you aware that shipping you the phone immediately was still an option if you wanted it. In any case, we are doing our best to resolve our phone backlog and resolve cases such as yours as well. Please give support a bit more time to get back to you.

@josh There are similar misconceptions about the Amish. It is just easier to dismiss avoidance of, and concerns about, negative consequences from some new technology by claiming it is all anti-technology.

@apples_and_pears Ahh I see. Yes I will definitely need to factor in the fact that the towels will shrink the first time they are washed and dried. It's just something I need to keep in mind when planning the dimensions for the towels.

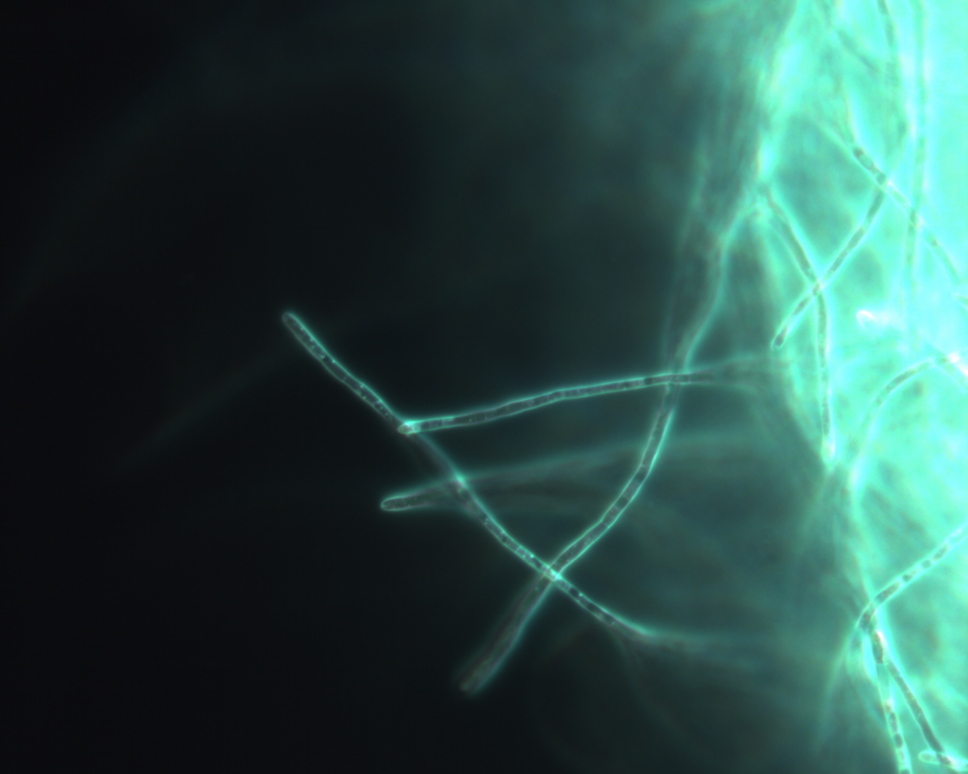

If anyone can't smell, perhaps this is the mod for your Librem 5.

https://youtu.be/Xv0gXfxCKEA

#Librem5 #BreakoutBoard, #anosmia #hacker #hardware

@apples_and_pears In what sense?

@Triffen The first time I dressed the loom for the towel project, it took about 13 hours before I started weaving, not just due to the complicated and dense pattern, but from having to correct threading mistakes I discovered while sleying the reed. This skips the risk of threading errors.

I'm not fast at tying weaver's knots yet, but after 576 chances to practice, I bet I'll be pretty fast by the end!

I'm weaving a new set of towels using the same doubleweave overshot pattern as the last set, but this time using yellow and brown unmercerized cotton.

Because the pattern is the same, I can save time by tying my new warp onto the remnants of the old warp that are still threaded in the loom. You simply use a weaver's knot to tie each individual new warp thread to a corresponding old warp thread and then wind it back on. Only about 550 warp threads to go!

@kop316 All I recall is a lot of kneading and pulling, folding, kneading some more, repeat, in very hot water. Similar to windowpane kneading for bread (which I know you are familiar with), you have to get those protein strands to relax (very hot water) and then line up and twist together (kneading and pulling).

@kop316 We only did it once. It requires a *lot* of heat (to the point that you need to wear those thick rubber gloves), and lots of kneading and pulling.

Now that the knitting machine is mounted on the board, you can really see how much space it would take up on the wall. We thought it over and decided to replace the large 48-hook version with the smaller 22-hook version.

Fortunately everything I did to the machine is reversible, and I still have the box and all the accessories. I know someone who I think will really like this one as a gift so it won't go to waste.

@KekunPlazas Congratulations!

@wobin It has 48 hooks, and will do a stitch every half hour, one round every day. The current plan is to knit a 365-round scarf for 2023. I will "cheat" and catch it up to the current day (whenever that is) when I get it done, and then have it take things from there.

I plan on marking significant days in the year with a colored thread. For instance, if I get this done by Valentine's Day, I will mark that with a red thread.

I’m sad to announce that I am leaving @themarkup to pursue other projects, which I will announce soon.

It was an honor and a privilege to found @themarkup five years ago to create an investigative newsroom that integrated engineers and journalists. We showed the world what journalism could be: math literate, computationally superpowered, and human-centered.

On my departure, I thought I would reflect on the ten lessons I learned leading these investigations. https://themarkup.org/hello-world/2023/02/04/journalistic-lessons-for-the-algorithmic-age

@whack I imagine it would follow whatever code is in place for low power wires (ie telephone wires and the like). I believe they are supposed to be in separate conduits from high power wires but beyond that I don't recall the rules (depth to bury, type of conduit to use).

More progress on my knitting clock. I've mounted all of the main components to the backer board. I also wired two buttons to GPIO pins and wrote a simple script to advance the machine forward and backwards one stitch with the buttons. I'll likely use this when I'm casting on and casting off.

The top of the clock will be where the stepper motor is. Now that I know how the pieces fit, I will cut the top so it is house-shaped, and build the sides and front of the clock.

- Personal Site

- https://kylerank.in

- Personal Bibliography

- https://kylerank.in/writing.html

Technical author, FOSS advocate, public speaker, Linux security & infrastructure geek, author of The Best of Hack and /: Linux Admin Crash Course, Linux Hardening in Hostile Networks and many other books, ex-Linux Journal columnist.