Final beer update: Keg time. I take my time when it comes to fermenting lagers, since at a minimum I want them to ferment for around three weeks and then lager for a few weeks after that. Sometimes I lager in the keg while it carbonates if I'm in a hurry, and other times in the fermenter.

As I transfer to the keg I collect a bit of the beer to take a final gravity reading for my brewing notebook (which I've maintained since 2009) and for a taste. Flat, but good!

Knitting clock update: I discovered the bottom case was a bit too tall so I took advantage of the fact that I needed to print it again to do a few other refinements.

I also took advantage of needing to transfer all of the components from the old case to the new to take a *lot* of pictures documenting the step-by-step process of assembling this.

The next step is to finish refining the lid that will cover the bottom case.

I recently invested in an 128oz mini-keg that fits in my fridge door. This lets me serve my homebrewed beer more conveniently than filling individual bottles. The downside is you can't tell at a glance how many more servings are in the keg.

The solution? I weighed the keg empty (~ 4 pounds) and now I can weigh the keg, subtract 4, and since a pint's a pound the world around, the number of pounds is approximately the number of pints left (in this case 5 pints).

I'm halfway through the second doubleweave overshot towel, and so far things are going smoothly and mistake-free! I probably won't do another update on this project until they are off the loom and hemmed, unless a fun disaster strikes.

More progress on my @hackaday -inspired knitting machine clock (code name Tempus Nectit)!

The bottom case printed successfully and I have mounted all of the major components: the Sentro 22-hook knitting machine, the stepper motor, power and the Raspberry Pi + Motor Hat.

I also wired two push buttons to what will be the bottom of the case that let you manually advance the knitting machine in each direction.

Next I design the front cover.

My son completed his first weaving project (he's 10). This white and red striped wool scarf was woven on a rigid heddle loom.

One towel down, two to go! From this angle you can see both sides and the reversible nature of this doubleweave pattern.

The second attempt is looking good for this 3D printed case for my knitting clock. Along with fixing some mistakes in my design, I also modified it so that it could print for the most part without supports. There was one area where that was unavoidable, so I added in basic supports. While there is a little cleanup where it bridged there, it's much less than I saw when I enabled internal supports in the first print.

See if you can spot the treadling errors! I managed to make the same mistake three different times in pattern repeats so far. Combined with the threading mitsake from earlier, this is rapidly becoming the "warm up" towel where I hopefully get all of the mistakes out of my system before the next two.

We are 40 hours in and the structure that holds the knitting machine itself is completed. All that is left are the walls which also have button and motor mounts in them.

After almost 16 hours, the case for my knitting clock is starting to take shape. You can now make out the central structure that will hold the knitting machine itself in place. While I tried to reduce overhangs, due to the nature of this model there still are quite a few so there will be a lot of internal support material to remove when this is done.

I've been quiet about my hackaday-inspired knitting clock project ever since I decided to replace the 48-hook machine with a 22-hook model, but that's because I've been busy learning 3D modeling!

I realized the new 22-hook knitting machine fits on my 3D printer bed, so instead of a wooden case, I designed a custom case for it using Tinkercad. I just started an epic 2 day, 8-hour print of the case that takes up my entire print bed!

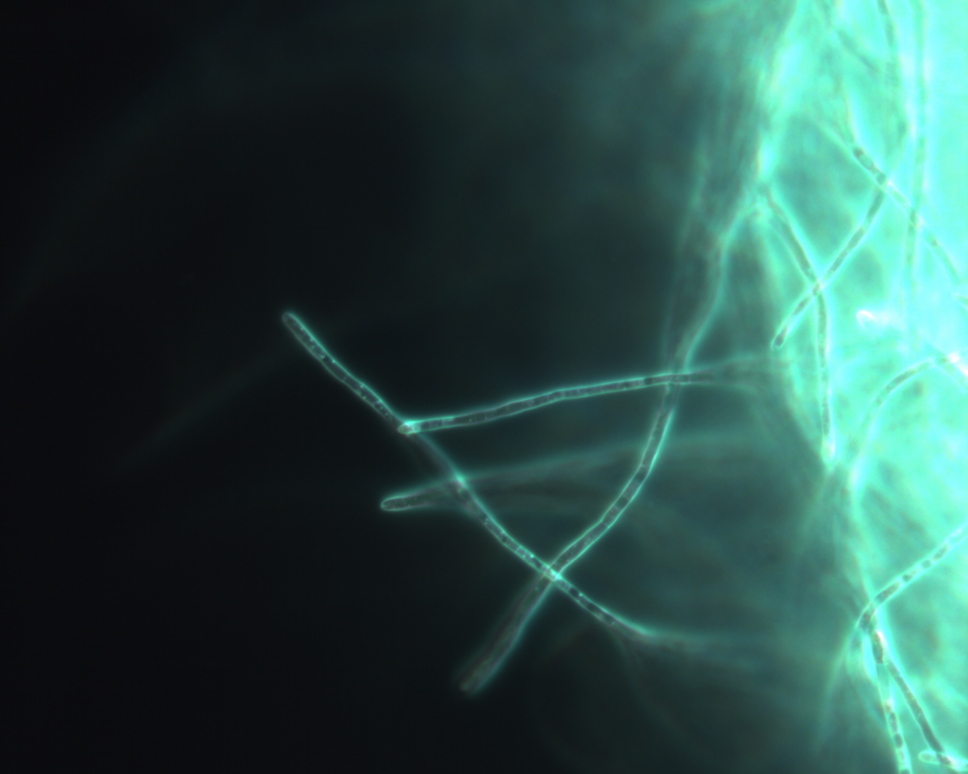

After weaving quite a few inches into the towel I thought something looked off and discovered I was missing a thread!

If you find the pin in the picture you can see that part of the pattern just looks a bit off. Follow that line up to where the thread finally is threaded and you can see where the pattern got corrected after I added a new warp thread.

I finished tying on the new warp to the old and have started weaving the first of three towels. Beyond the different colored yarn, I also modified this design in two ways, taking advantage of the reversible nature of this doubleweave overshot pattern:

1. Since there is no "right" side to this, I reversed the color for almost 2/3 of the hem at the bottom so when I fold it, it matches the color on its own side.

2. I extended the inverted color of the pattern stripe.

Halfway through tying a new warp onto the remnants of the old. Wow this is tedious work, and there is at least 3 more hours to go, but I still think it is faster and less error-prone than re-threading it.

I'm weaving a new set of towels using the same doubleweave overshot pattern as the last set, but this time using yellow and brown unmercerized cotton.

Because the pattern is the same, I can save time by tying my new warp onto the remnants of the old warp that are still threaded in the loom. You simply use a weaver's knot to tie each individual new warp thread to a corresponding old warp thread and then wind it back on. Only about 550 warp threads to go!

More progress on my knitting clock. I've mounted all of the main components to the backer board. I also wired two buttons to GPIO pins and wrote a simple script to advance the machine forward and backwards one stitch with the buttons. I'll likely use this when I'm casting on and casting off.

The top of the clock will be where the stepper motor is. Now that I know how the pieces fit, I will cut the top so it is house-shaped, and build the sides and front of the clock.

I knitted a shawl! Well, the flatbed knitting machine did a lot of the work, but I helped. This was the second attempt as I ran out of yarn halfway through for the first attempt and the local yarn store only had the single skein. I ended up selecting a different yarn for this attempt.

- Personal Site

- https://kylerank.in

- Personal Bibliography

- https://kylerank.in/writing.html

Technical author, FOSS advocate, public speaker, Linux security & infrastructure geek, author of The Best of Hack and /: Linux Admin Crash Course, Linux Hardening in Hostile Networks and many other books, ex-Linux Journal columnist.