I *think* I have managed to talk myself out of getting a very affordable used 60" production mechanical dobby loom with all the automated attachments.

One against it is the fact that it would only fits in my garage, and by the time I could clear out the space it would likely be gone. Do I really want to do production weaving in my dusty garage?

Finally, I guess the biggest argument is that I can't justify actually doing mass production weaving since this is just a hobby.

I'm halfway through the second doubleweave overshot towel, and so far things are going smoothly and mistake-free! I probably won't do another update on this project until they are off the loom and hemmed, unless a fun disaster strikes.

My son completed his first weaving project (he's 10). This white and red striped wool scarf was woven on a rigid heddle loom.

One towel down, two to go! From this angle you can see both sides and the reversible nature of this doubleweave pattern.

See if you can spot the treadling errors! I managed to make the same mistake three different times in pattern repeats so far. Combined with the threading mitsake from earlier, this is rapidly becoming the "warm up" towel where I hopefully get all of the mistakes out of my system before the next two.

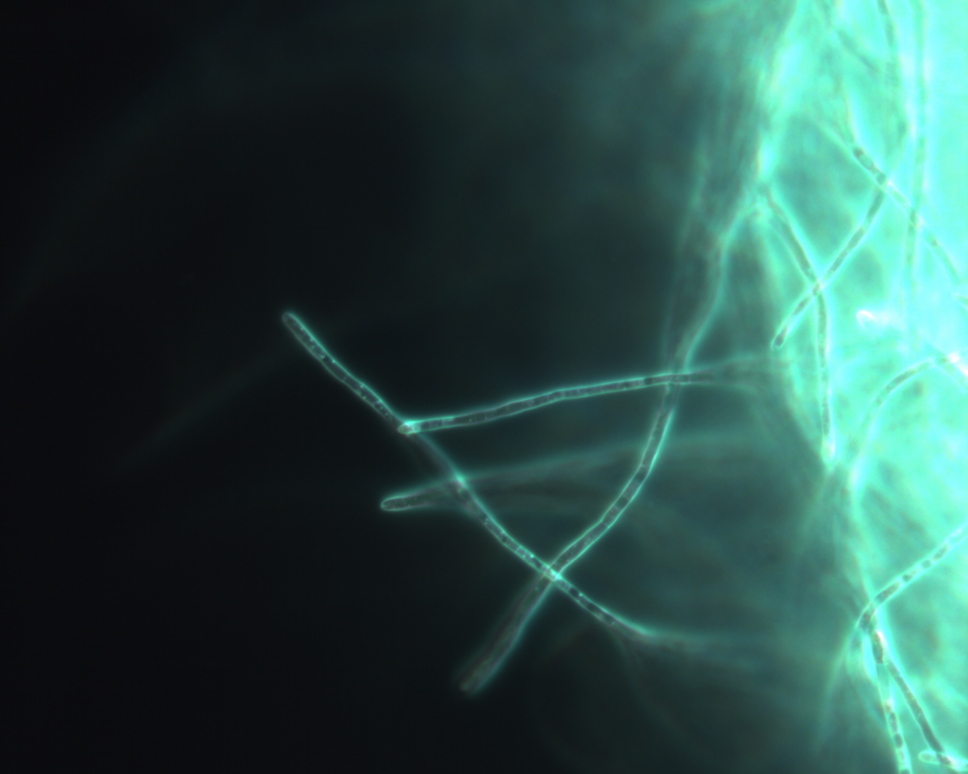

After weaving quite a few inches into the towel I thought something looked off and discovered I was missing a thread!

If you find the pin in the picture you can see that part of the pattern just looks a bit off. Follow that line up to where the thread finally is threaded and you can see where the pattern got corrected after I added a new warp thread.

I finished tying on the new warp to the old and have started weaving the first of three towels. Beyond the different colored yarn, I also modified this design in two ways, taking advantage of the reversible nature of this doubleweave overshot pattern:

1. Since there is no "right" side to this, I reversed the color for almost 2/3 of the hem at the bottom so when I fold it, it matches the color on its own side.

2. I extended the inverted color of the pattern stripe.

Halfway through tying a new warp onto the remnants of the old. Wow this is tedious work, and there is at least 3 more hours to go, but I still think it is faster and less error-prone than re-threading it.

I'm weaving a new set of towels using the same doubleweave overshot pattern as the last set, but this time using yellow and brown unmercerized cotton.

Because the pattern is the same, I can save time by tying my new warp onto the remnants of the old warp that are still threaded in the loom. You simply use a weaver's knot to tie each individual new warp thread to a corresponding old warp thread and then wind it back on. Only about 550 warp threads to go!

- Personal Site

- https://kylerank.in

- Personal Bibliography

- https://kylerank.in/writing.html

Technical author, FOSS advocate, public speaker, Linux security & infrastructure geek, author of The Best of Hack and /: Linux Admin Crash Course, Linux Hardening in Hostile Networks and many other books, ex-Linux Journal columnist.