Thank you everyone for all of your great suggestions. It seems the consensus is to try out Tinkercad first so that's what I will do.

Hello 3D printing and CAD folks, I would like some advice:

I want to introduce my 10-year-old son to simple 3D modeling and CAD so he could design objects to send to our 3D printer. I am looking for software that is easy to use, even if functionality is limited, FOSS if possible. I have no CAD skills myself, and opening FreeCAD for the first time was pretty intimidating. I would also prefer something GUI/mouse-based, not declarative (ie not OpenSCAD).

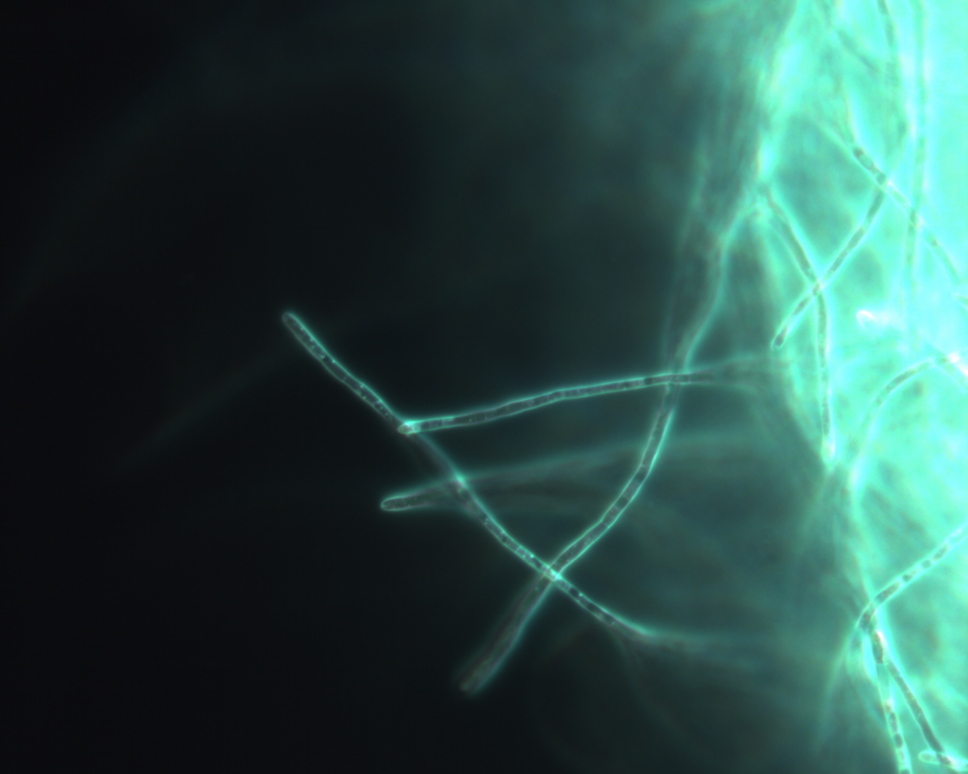

Beer Update: It's alive! The first few days the beer was perfectly still with no sign of life (the yeast were reproducing), but now a week in you can see bubbles on the top and the airlock is bubbling away. This means the yeast is alive and happily converting sugars into alcohol and CO2.

This is a lager yeast so it will hang out more at the bottom of the container compared to ale yeasts. In a few weeks they will run out of food and settle to the bottom.

Walking through Universal Studios seeing a lot of Harry Potter scarves. I guess I am getting some confidence as a weaver (and even a machine knitter) because after inspecting one up close in a shop my first thought was "oh, I could make something better than that easily..." #weaving #knitting #machineknitting

If you are using mobile linux with T-mobile/a T-mobile MVNO, you may have noticed that sending MMSes stopped working recently.

I figured out the issue and released a new version of mmsd-tng to fix it:

https://gitlab.com/kop316/mmsd/-/tags/2.1.0

https://gitlab.com/kop316/mmsd/-/tags/1.13.0 .

1.x uses libsoup2 and 2.x uses libsoup3, there shouldn't be any differences between the versions besides that.

My book on facial recognition technology comes out on September 19! Over the last two years, I tracked down the tech's early pioneers, found the people fighting against its worst impulses, and dove into the history of Clearview AI, the start-up that first drew me into the topic with a radical person-finding app that giants in the field, including Google and Facebook, had deemed taboo. It feels real now because there's a release date and a preorder button: https://www.penguinrandomhouse.com/books/691288/your-face-belongs-to-us-by-kashmir-hill/

I thought it would be nice to begin the year with a little Sense and Sensibility. I haven't read this novel yet, but I really enjoyed Pride and Prejudice when I read it about two years back so I have great expectations.

Looking for people who know something about early computing, especially in the Netherlands. Please boost and help me solve the mystery of this custom made plate that used to belong to my grandfather Bram Jan Loopstra, one of the pioneers of Dutch computing. What do the pictures mean? #computing #history

All that's left is for me to clean my equipment. With the Grainfather this means pouring some water into it, adding some brewing cleaning (PBW in my case) heat the water, and then pump it through it and the counterflow chiller for 10 minutes, replace with fresh water, and then rinse for 10 minutes.

Thank you everyone who stuck with the thread to this point. It was fun sharing the brewing day with everyone. Feel free to post any questions you may have.

With the last bit of wort pumped into the carboy, I pitch my yeast, add an airlock to the top, fill it with vodka, and the brewing process is done. I will move the carboy to a temperature-controlled chamber where it will ferment for a few weeks, then lager for a few more weeks, before I transfer it to a keg.

As the wort pumps into the carboy, I redirect a bit into a cylinder so I can take a gravity measurement (in this case I was right on target: 1.050!). This measures the specific gravity of the liquid compared to plain water and approximates the amount of sugar you have in your wort. Later when the beer is done fermenting I will take another reading and use the difference to determine how much sugar was converted into alcohol.

With enough cool water flowing through the system, the counterflow chiller can chill the wort enough to go into the fermentation vessel (plastic carboy) within a few minutes. I have an in-line thermometer I use to monitor the temperature of the wort leaving the counterflow chiller and when it's within the right range I stop the pump, move the wort output to my carboy, and start the pump again, pumping the cool wort into the carboy.

The counterflow chiller is a heat exchanger with two inputs and two outputs. Hot wort is pumped through one input and exits back into the kettle. The blue tube is an input attached to a cool water source (garden hose) and the red tube is the output of that water source. As the hot wort and cool water flow through the chiller, the heat is exchanged, cooling the wort and heating the water. I collect the hot wastewater and re-use it for cleaning the kettle later.

The boil is done so I've attached my counterflow chiller to my Grainfather pump and I'm recirculating boiling wort through it for 10 minutes to sanitize the inside of it before I connect it to cool water to actually chill the wort. I also filled my fermentation vessel with sanitizing solution for 10 minutes so it will be disinfected when I'm ready to transfer wort to it.

I have about 30 minutes before I need to do the next step in the brewing process, and everything I can clean is clean, so now's a good time if anyone had any questions or wanted more specific details about brewing in general or my brewing specifically.

Now for the first (and for this recipe only) hop addition with 60 minutes left in the boil. These are whole leaf Cascade hops that we harvested from our hop plant in our garden this summer.

Adding hops at this stage of the boil extracts compounds that make the beer taste more bitter. These compounds are also anti-microbial and help protect the beer from infection post-boil, especially in the sensitive stage before the yeast make any alcohol.

We are about 30 minutes into a 90 minute boil. If you look closely at this picture you can see light tan bits that aren't foam, that seem to be floating to the top. This is known as "hot break" and are proteins that are cooking out of the wort during the boil. This is something we want to happen and is one of the reasons for the boil.

The lautering/sparging process is complete so I removed the top grain basket and now we are waiting for the wort to reach a boil. What do we do while we wait? We clean of course! I dumped the spent grain into the compost bin and cleaned the grain basket and lauter kettle and all mashing and lautering equipment. In a minute I will start stirring the foam at the top of the kettle back into the wort so it doesn't boil over when it hits boiling temps.

After mashing, I lift the interior metal basket and rest it at the top of the Grainfather. There is a mesh at the bottom of this basket which allows the sticky, sweet brown liquid called wort to drain into the kettle while leaving the grain behind.

While the kettle heats up to boiling, I start rinsing the top of the grain with hot water from my lauter tun. This water trickles through the grain bed and extracts more sugars as it drips down into the kettle.

After mashing, the next step is the lautering process, where I remove the grain from the mash water and rinse it with hot water to extract more remaining sugars.

This is my lauter tun. It's an electric brewing kettle that I used to brew beer with before I got my Grainfather. I fill this kettle with the appropriate amount of water, heat it to the proper temp, and then connect a hose to a spout at the bottom and use gravity to move the water to my Grainfather.

- Personal Site

- https://kylerank.in

- Personal Bibliography

- https://kylerank.in/writing.html

Technical author, FOSS advocate, public speaker, Linux security & infrastructure geek, author of The Best of Hack and /: Linux Admin Crash Course, Linux Hardening in Hostile Networks and many other books, ex-Linux Journal columnist.