How do I know when the wort is cool? I have an inline thermometer connected to the wort output on the counterflow chiller.

We must cool the wort to room temp so we don't kill the yeast we add later. The Grainfather comes w/ a counterflow chiller that makes this fast. Pump hot wort through 1 tube, cool water the other. Heat exchanges inside, cool wort goes back to the kettle, hot water to a bucket.

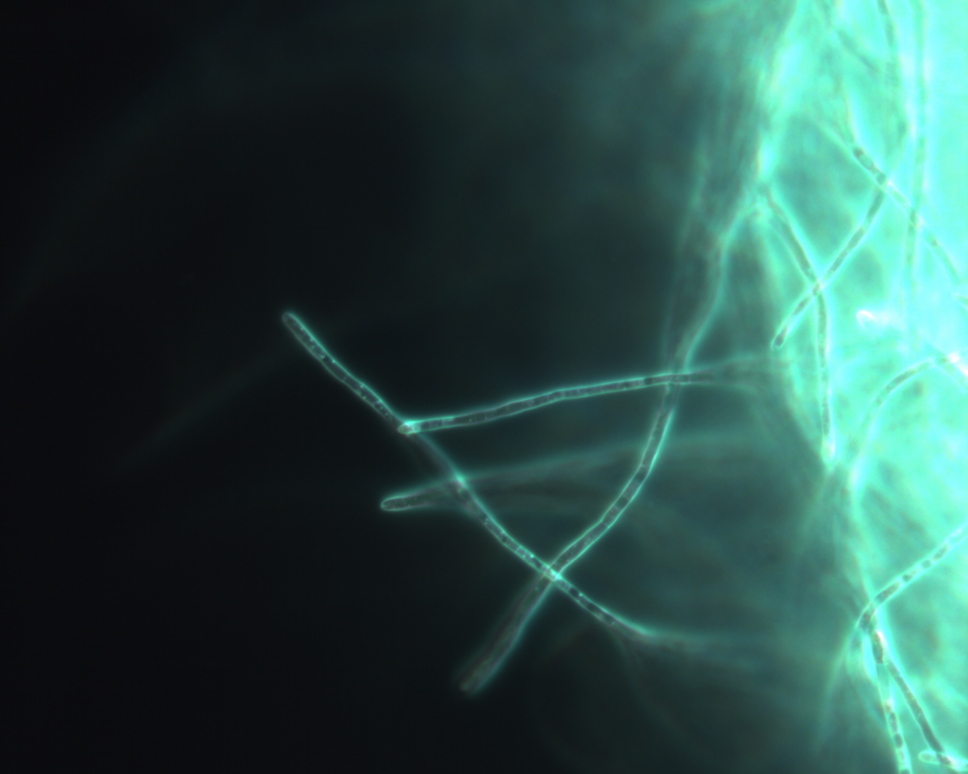

Ten minutes before the end of the boil I connect my counterflow chiller to the pump and recirculate boiling wort through it. Up to now we haven't been concerned with sterilization but after the boil everything the wort touches must be sterile including inside this chiller.

Cleaning part 1! While we wait for the boil to finish it's a great time to clean up equipment we aren't using for the rest of the process.

Adding hops with 60 mins left in the boil. Hops boiled this long produce a bitter flavor and are called "bittering hops". Originally hops were added because it extracts an antibiotic oil, lupulin, which helps prevent infection in the beer, particularly before alcohol is present.

The boil! This recipe calls for a 90min boil but most are 60 mins. We boil wort for a few reasons:

1. Cooking. Maillard reactions develop flavor in the wort

2. Sterilization. Wort is sticky, sugary stuff. Boiling kills microorganisms in the barley that'd infect the beer.

Now we "sparge" or rinse the remaining sugar out of the grain with 10L of 75C water in 1L batches from my electric kettle. The internal grain basket lifts out and rests on top of the kettle so wort and sparge water can drain into the boil kettle that is heating up to 98C.

One the mash completes, we start the "mash out" step. This heats what we can officially call "wort" (pre-beer or sugary barley liquid) up to 75C to denature the enzymes and stop the creation of any more sugars. This also makes it easier to rinse out more sugar in the next step.

Halfway through the mash you can see the effect of recirculating liquid through the grain. The husks and perforated bottom are filtering as they should and the cloudy liquid from 30 minutes ago is much clearer.

While I wait for the mash to complete, I take notes in a notebook I've used for years to track my brewing. This makes it easier to repeat beers I like, and review my notes if something doesn't work out.

Now we mash for an hour. The pump recirculates liquid through the grain. Enzymes (alpha and beta amylase) in malted barley convert starches into sugars (maltose and glucose). Each enzyme has different but overlapping ideal temp ranges to convert starch, both are active at 68C.

Now we add our pre-crushed malted barley to the water a bit at a time, stirring in between. This process is called "douging in" and you are basically making a giant barley porridge.

As the water heats up I drop in the mash tun insert. It has a perforated bottom that prevents most of the grain from getting through, and it plus the barley husks in my mash ultimately act as a filter so only liquid gets through as we recirculate it.

Step one, add the "strike water" (what we steep the grain in) and heat it to 68C, the temperature we need to "mash" the grain (essentially steep it like with tea).

I was able to install @micahflee 's dangerzone package on my #Librem5 and w/ some QT tweaks the main screen fits (other screens need more work). It uses an amd64 Docker image so I need an arm64 image to actually clean docs, but it was nice that I got as far as I did without much effort.

The latest changes to hit the #Librem5 staging repo have dramatically increased my quality of life. First, Chatty now can use the haptic motor so I get vibration notifications w/ messages. Second, the top menu bar now features quick access to more settings.

Apparently when you move a registered Google Fi SIM to a new phone w/o re-registering it w/ the Fi app, incoming SMS have 16 random chars appended to the end. I assume registration causes local apps to hide the text. I wonder what Google is using those strings for?

https://www.reddit.com/r/ProjectFi/comments/5k3h9t/texts_ending_with_tilde_and_random_letters/

Having brisket for dinner yesterday meant waking up at 2am to put the meat in the smoker by 3. After a 13 hour smoke and an hour rest, it was perfect. I think I've finally figured out my technique. #bbq #brisketlogistics

- Personal Site

- https://kylerank.in

- Personal Bibliography

- https://kylerank.in/writing.html

Technical author, FOSS advocate, public speaker, Linux security & infrastructure geek, author of The Best of Hack and /: Linux Admin Crash Course, Linux Hardening in Hostile Networks and many other books, ex-Linux Journal columnist.