The counterflow chiller is a heat exchanger with two inputs and two outputs. Hot wort is pumped through one input and exits back into the kettle. The blue tube is an input attached to a cool water source (garden hose) and the red tube is the output of that water source. As the hot wort and cool water flow through the chiller, the heat is exchanged, cooling the wort and heating the water. I collect the hot wastewater and re-use it for cleaning the kettle later.

The boil is done so I've attached my counterflow chiller to my Grainfather pump and I'm recirculating boiling wort through it for 10 minutes to sanitize the inside of it before I connect it to cool water to actually chill the wort. I also filled my fermentation vessel with sanitizing solution for 10 minutes so it will be disinfected when I'm ready to transfer wort to it.

I have about 30 minutes before I need to do the next step in the brewing process, and everything I can clean is clean, so now's a good time if anyone had any questions or wanted more specific details about brewing in general or my brewing specifically.

Now for the first (and for this recipe only) hop addition with 60 minutes left in the boil. These are whole leaf Cascade hops that we harvested from our hop plant in our garden this summer.

Adding hops at this stage of the boil extracts compounds that make the beer taste more bitter. These compounds are also anti-microbial and help protect the beer from infection post-boil, especially in the sensitive stage before the yeast make any alcohol.

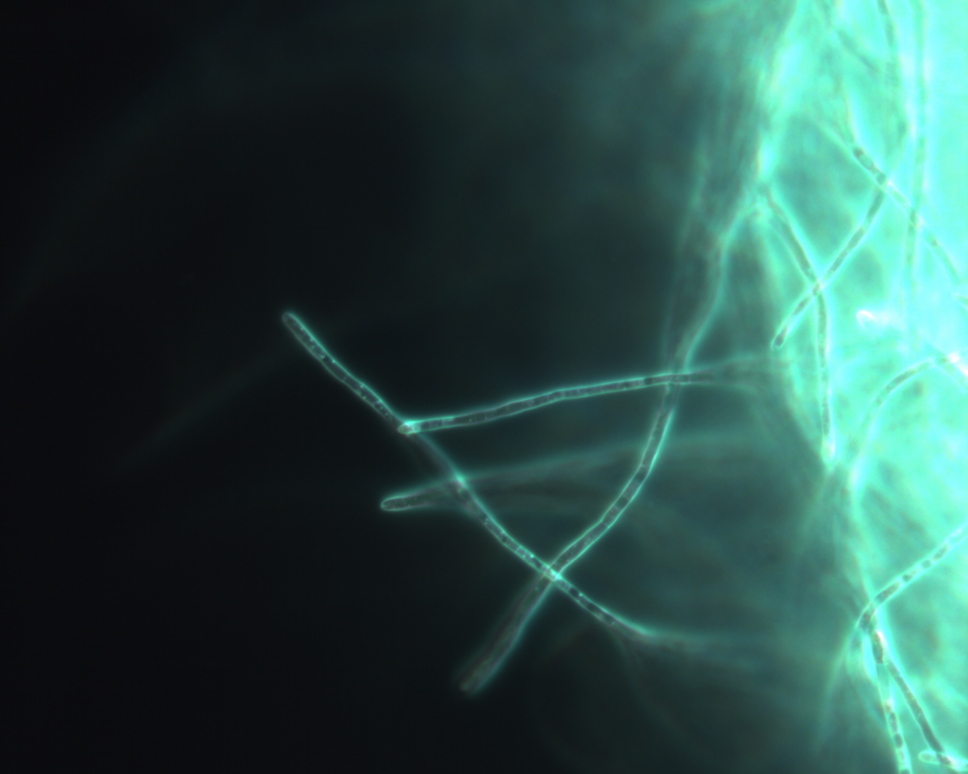

We are about 30 minutes into a 90 minute boil. If you look closely at this picture you can see light tan bits that aren't foam, that seem to be floating to the top. This is known as "hot break" and are proteins that are cooking out of the wort during the boil. This is something we want to happen and is one of the reasons for the boil.

The lautering/sparging process is complete so I removed the top grain basket and now we are waiting for the wort to reach a boil. What do we do while we wait? We clean of course! I dumped the spent grain into the compost bin and cleaned the grain basket and lauter kettle and all mashing and lautering equipment. In a minute I will start stirring the foam at the top of the kettle back into the wort so it doesn't boil over when it hits boiling temps.

After mashing, I lift the interior metal basket and rest it at the top of the Grainfather. There is a mesh at the bottom of this basket which allows the sticky, sweet brown liquid called wort to drain into the kettle while leaving the grain behind.

While the kettle heats up to boiling, I start rinsing the top of the grain with hot water from my lauter tun. This water trickles through the grain bed and extracts more sugars as it drips down into the kettle.

After mashing, the next step is the lautering process, where I remove the grain from the mash water and rinse it with hot water to extract more remaining sugars.

This is my lauter tun. It's an electric brewing kettle that I used to brew beer with before I got my Grainfather. I fill this kettle with the appropriate amount of water, heat it to the proper temp, and then connect a hose to a spout at the bottom and use gravity to move the water to my Grainfather.

Even though I need to wait 90 minutes for the next step of the process, I'm not sitting here idle. A key part of having an enjoyable brew day, I've found, is to clean up incrementally during these down times, and prepare everything for the next step. For instance, after I started the mashing process, I put away all of the grain grinding equipment and my bag of bulk barley, swept loose grain from the floor, and now I'm preparing my lauter tun for the next step.

During this 90 minute mashing process enzymes in the malted barley convert starches into simple sugars like alpha and beta amylase. The ideal temp to convert each of these sugars is different, so recipes pick temps somewhere in the middle based on which sugars they want the most of. This choice can affect the body and residual sweetness left in the beer after fermentation.

Once all the grain is added I add a mesh screen above the water level in the kettle, attach a recirculation arm to my Grainfather's pump and tell it to start the 90 min mashing process. It recirculates water throughout the process to improve efficiency and clarity in the beer.

After the water heats up I can "dough in" or add my ground grain to the mash water. I have a long metal mashing paddle that makes it easier to stir the grain as I add it to remove clumps, which helps improve mashing efficiency later. Basically you are making a barley porridge and the consistency at the end is pretty similar to oatmeal.

While the mash water heats up, I grind my grain using a hand grinder. For some recipes I get my malted barley pre-ground, but I have started buying my base malt in bulk, and the barley comes whole.

Grinding the grain removes the kernel from the husk and exposes more of the starch to the water so the mashing process is much more efficient. Malted barley contains an enzyme that will convert starches in the barley to sugar when immersed in water. #brewing #happybrewyear #beer

Happy Brew Year! Today I'm going to brew a simple Mexican-style dark Lager which traditionally were based on a Vienna dark lager but with US ingredients including flaked corn. In this thread I will document my brew day.

The first step is to heat up my mash water. I brew beer using a Grainfather brewing system, which automates a lot of the process for me and shaves a few hours off of my brew day. #brewing #happybrewyear #beer

My 2022 temperature blanket is done.*

365 days

2 rows a day

730 rows**

360 stitches per row

262,800 stitches**

Roughly 20 minutes per row

Approximately 250 hours of knitting

Temperatures from -5ºC - 35ºC

19 colours of yarn

And impossible to photograph all in one go, because it's BIG - roughly 6ft wide and over 6ft in length.

* Though I'm probably going to add a crochet border.

** Not including cast on / off and setup rows.

When I visited Canada I was surprised at how much better the chocolate, even the inexpensive mass-produced chocolate, tasted compared to comparable brands in the US.

I could be because Canada has tighter regulations on % of chocolate in their recipes, but today I learned it was probably also the lack of lead and cadmium: https://metro.co.uk/2022/12/29/hershey-facing-lawsuit-over-heavy-metals-found-in-their-chocolates-18012980/

Annual reminder that while many #cybersecurity professionals are also deeply invested and interested in privacy, sometimes the two align and sometimes they’re opposed to one another in practicality. Always be conscious of when you’re sacrificing your (and more importantly other peoples’) privacy for the sake of security, and be very careful and measured about those decisions. Lost privacy rarely comes back. Not in business, and not in society at large.

My son asked if I would teach him how to weave so yesterday he learned how to warp a rigid heddle loom and the basics of plain weaving. Now he is busy making his mother a scarf. I'm wishing I had a smaller rigid heddle loom, this 32" Kromski is not ideal for a kid. That said, his beat is pretty consistent and he's doing a decent job managing his selvedges so far. #weaving

- Personal Site

- https://kylerank.in

- Personal Bibliography

- https://kylerank.in/writing.html

Technical author, FOSS advocate, public speaker, Linux security & infrastructure geek, author of The Best of Hack and /: Linux Admin Crash Course, Linux Hardening in Hostile Networks and many other books, ex-Linux Journal columnist.